Titanium alloy parts Tractor Part/Metal Sand Machinery/Machined Steel /Mechanical/Motor Parts for Compressor Body

|

Material |

Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, AL2024 |

| Stainless steel: SS201, SS301, SS303, SS304, SS316, SS430 etc | |

| Steel: mild steel/ carbon steel including 1010, 1020, 1045, 1050, Q690 etc | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |

| Copper: C11000, C12000, C12000, C17200, C72900, C36000 etc. | |

|

Processing |

Germany Trumpf brand Laser cutter, CNC shearing machine, CNC bending machine, |

| (CNC) stamping machine, Hyraulic Machine, Various welding machine, CNC machine center. |

|

|

Surface |

Aluminum: Anodization, Sandblast, Brushing, Polishing, Electro-plating etc |

| Stainless Steel: Polishing, Brushing, Passivating, Sandblasting, Electro-plating | |

| Steel: Zinc plating, Nickel plating, Chrome plating, Powder Coating, Painting etc | |

| Brass & Copper: Brushing, Polishing etc | |

|

Precision |

+ - 0.1mm |

|

Application |

Railway, Auto, Truck, Medical, Machinery, Equipment, Electronic, Electrical etc |

Titanium is a new type of metal. The performance of titanium is related to the content of impurities such as carbon, nitrogen, hydrogen and oxygen. The content of impurities in the purest titanium iodide is less than 0.1%, but its strength is low and plasticity is high.The properties of 99.5% industrial pure titanium are as follows: density ρ=4.5g/cm3, melting point 1725℃, thermal conductivity λ=15.24W/(m.K), tensile strength σb=539MPa, elongation δ=25%, section shrinkage ψ=25%, modulus of elasticity E=1.078×105MPa, hardness HB195.

High strength

The density of titanium alloy is generally about 4.51g/cm3, only 60% of steel, and some high strength titanium alloys exceed the strength of many alloy structural steels.Therefore, the specific strength (strength/density) of titanium alloy is much greater than that of other metal structural materials, which can produce parts with high unit strength, good rigidity and light weight.Aircraft engine components, skeleton, skin, fasteners and landing gear all use titanium alloy.

High thermal strength

The use temperature is a few hundred degrees higher than the aluminum alloy, can still maintain the required strength at medium temperature, can work for a long time at 450 ~ 500℃ temperature. These two kinds of titanium alloy in 150℃ ~ 500℃ range still have a very high specific strength, and aluminum alloy at 150℃ specific strength decreased significantly.The working temperature of titanium alloy can reach 500℃, while that of aluminum alloy is below 200℃.

Good resistance to corrosion

The corrosion resistance of titanium alloy is much better than that of stainless steel in wet atmosphere and sea water.Pitting corrosion, acid corrosion, stress corrosion resistance is particularly strong;It has excellent corrosion resistance to alkali, chloride, chlorine organic products, nitric acid, sulfuric acid, etc.But the corrosion resistance of titanium to reducing oxygen and chromium medium is poor.

Good low temperature performance

Titanium alloy can maintain its mechanical properties at low and ultra-low temperatures.Titanium alloys with good low temperature performance and very low interstitial elements, such as TA7, can maintain a certain plasticity at -253℃.Therefore, titanium alloy is also an important low temperature structural material.

High chemical activity

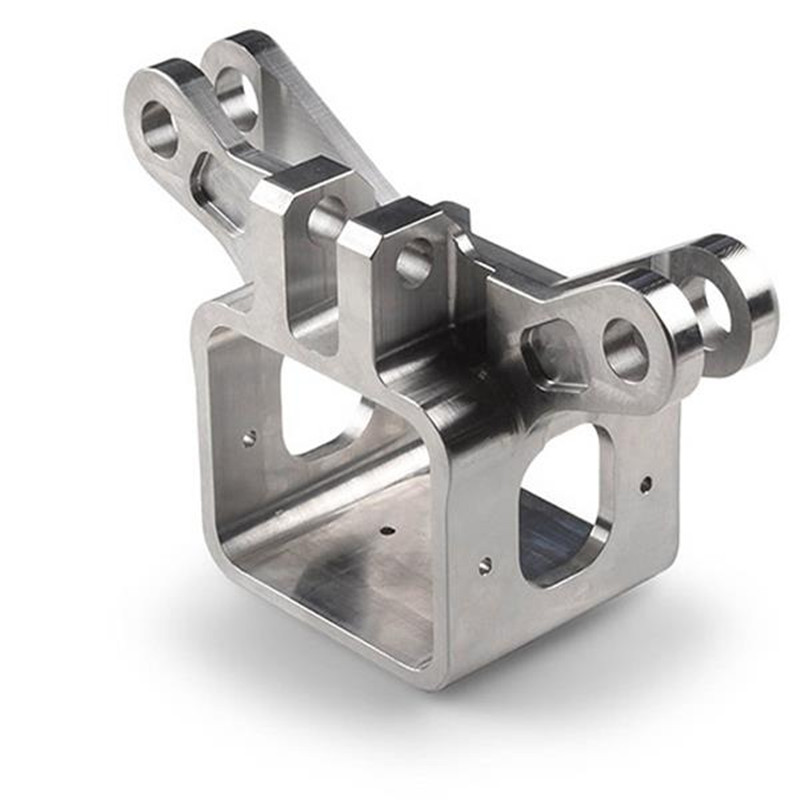

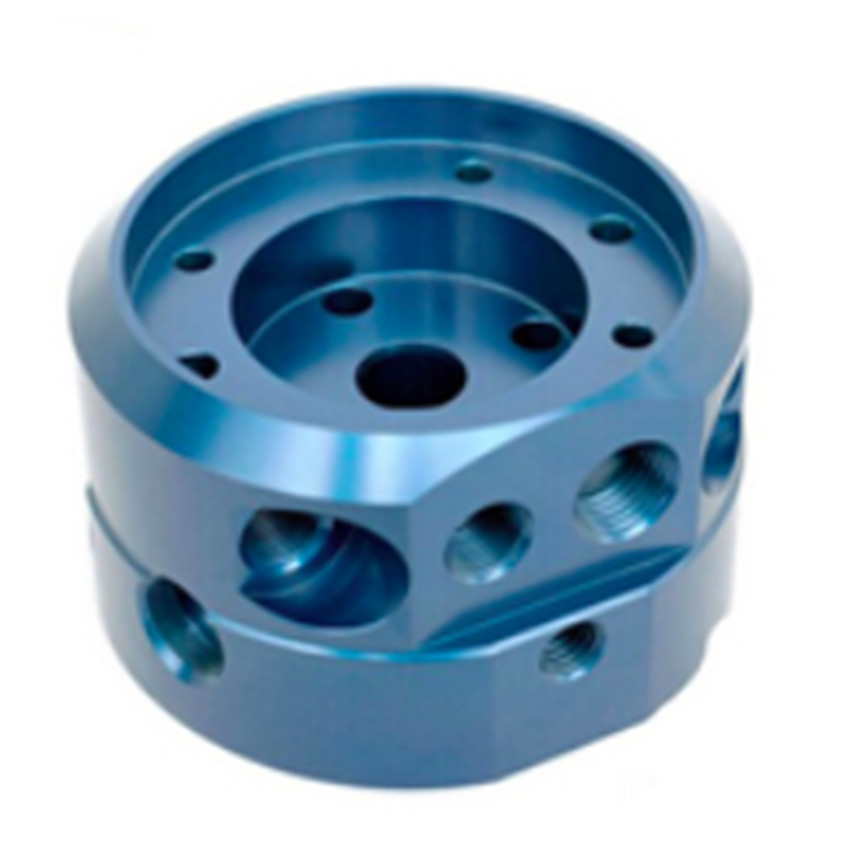

Titanium alloy products

Titanium alloy products

Titanium has a strong chemical reaction with O2, N2, H2, CO, CO2, water vapor, ammonia and other gases in the atmosphere.When the carbon content is greater than 0.2%, hard TiC will be formed in the titanium alloy.When the temperature is high, the hard surface layer of TiN will be formed by the interaction with N.When the temperature is above 600℃, the titanium absorbs oxygen and forms a hardened layer with high hardness.As the hydrogen content rises, a brittle layer will also form.The depth of the hard and brittle surface layer produced by the absorption of gas can reach 0.1 ~ 0.15 mm, and the hardening degree is 20% ~ 30%.Titanium chemical affinity is also large, easy to produce adhesion with the friction surface.

Small thermal conductivity elasticity

The thermal conductivity of titanium (λ=15.24W/(m·K)) is about 1/4 of that of nickel, 1/5 of that of iron, 1/14 of that of aluminum, and the thermal conductivity of various titanium alloys is about 50% lower than that of titanium.The elastic modulus of titanium alloy is about 1/2 of steel, so its rigidity is poor, easy to deformation, should not be made of slender rod and thin-walled parts, cutting when the processing of the surface of the rebound is large, about 2 ~ 3 times of stainless steel, resulting in severe friction, adhesion, adhesive wear on the tool surface.