Steel Forging

-

OEM Custom Brass Forged Part

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Machinery Parts

Machining: CNC Machining

Material: SS

Surface Treatment: Polishing

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, CE, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

Precision Heavy Steel Forging with Chrome Plated

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Auto Parts

Machining: CNC Machining

Material: Steel

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

OEM Customized Steel Forging Parts

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Auto Parts

Machining: CNC Machining

Material: Steel

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

OEM Customized Stainless Steel Forging Ring

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Machinery Parts

Machining: CNC Machining

Material: SS

Surface Treatment: Polishing

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, CE, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

General Die Forging Steel Ring

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Machinery Parts

Machining: CNC Machining

Material: SS

Surface Treatment: Polishing

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, CE, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

Heavy Duty Forged Steel Shaft

Basic Info

Processing Object: Metal

Molding Style: Forging

Molding Technics: Pressure Casting

Application: Machinery Parts

Machining: CNC Machining

Material: SS

Surface Treatment: Polishing

Forging Tolerance: +/-0.1mm

Standard: ANSI

Certification: SGS, CE, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin -

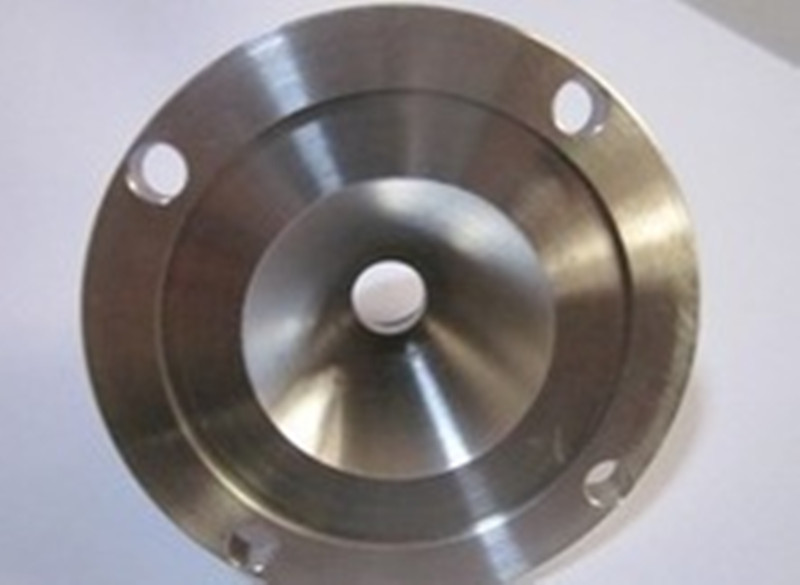

Custom forged parts

product presentation:

The forging machine is used to produce plastic deformation by exerting pressure on the metal blank to obtain the forging with certain mechanical properties, shape and size.Through the continuous hammering of pipe fitting, the original segregation, porosity, porosity, slag and other compaction and bonding in the ingot become more compact, and the plastic and mechanical properties of the metal are improved.Forging pipe fittings mainly includes forging flange, forging reducing pipe, forging tee, etc.The main materials of forged pipe fittings are Q235, Q345, 16Mn,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With corresponding forging fittings is casting fitting, the mechanical properties of castings below forgings with the same material mechanical properties, casting pipe fittings metal melting into complying with the requirements of a certain liquid and poured into the mold, after cooling solidification, men get a predetermined shape, size and performance of the casting parts (or blank) process.[1]

-

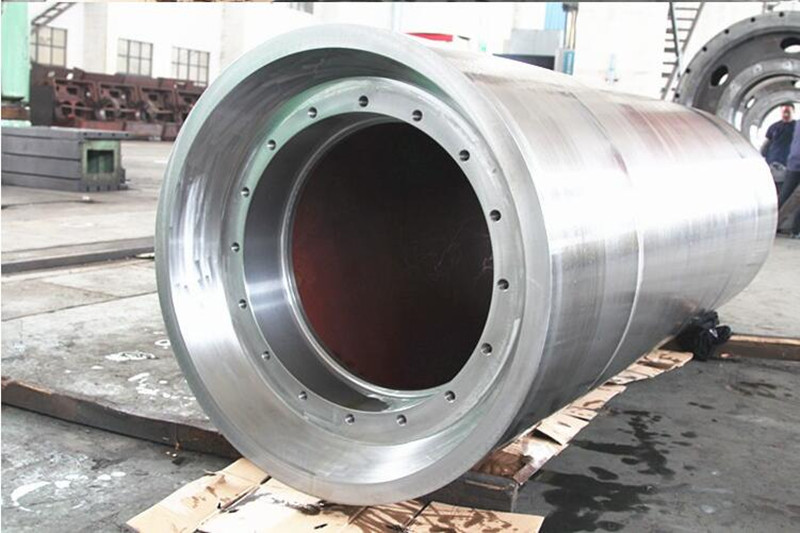

Forging steel pipe

product presentation:

The forging machine is used to produce plastic deformation by exerting pressure on the metal blank to obtain the forging with certain mechanical properties, shape and size.Through the continuous hammering of pipe fitting, the original segregation, porosity, porosity, slag and other compaction and bonding in the ingot become more compact, and the plastic and mechanical properties of the metal are improved.Forging pipe fittings mainly includes forging flange, forging reducing pipe, forging tee, etc.The main materials of forged pipe fittings are Q235, Q345, 16Mn,20#,35#,45#,40Cr,12Cr1MoV, 30CrMo,15CrMo, 20G, etc.With corresponding forging fittings is casting fitting, the mechanical properties of castings below forgings with the same material mechanical properties, casting pipe fittings metal melting into complying with the requirements of a certain liquid and poured into the mold, after cooling solidification, men get a predetermined shape, size and performance of the casting parts (or blank) process.[1]