Reasonable price Brake Disc - OEM Custom Aluminium Die Casting Part – Mingda

Reasonable price Brake Disc - OEM Custom Aluminium Die Casting Part – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

There are a number of different aluminum alloys we currently use for aluminium casting parts. Each material grade (listed in the chart below) offers varying chemical breakdowns and mechanical properties. Our aluminium parts can range in sizes from less than one ounce up to 30KG. By strictly following the TS16949 standards, we have optimized equipment operator functions. This has resulted in our [supply chain niche” of being able to consistently produce high grade aluminum alloy parts with annual usages from thousands to millions.

Our manufacturing facility has automated LK and Toshiba machines with clamping pressure tonnages that range from 160T to 2,500T. This allows us to cast a wide range of very durable, precise shapes and components for a various original equipment manufacturer industry fields and applications from a few grams to over 35 pounds. Little or no machining is required after a part is die cast, because the process provides very close tolerances for even complex shapes. Aluminum die castings can also be easily plated or finished.

Our aluminum die cast services have assisted OEMs all over the world with producing parts at lower costs with unrivaled consistency, professionalism and delivery. Our manufacturing expertise, pair with our state-of-the-art machinery, assures that our aluminum alloy parts will receive the highest grade alloy materials and casting processes. We have the necessary experience and expertise to ensure all phases of the manufacturing process and delivering schedules to our clients.

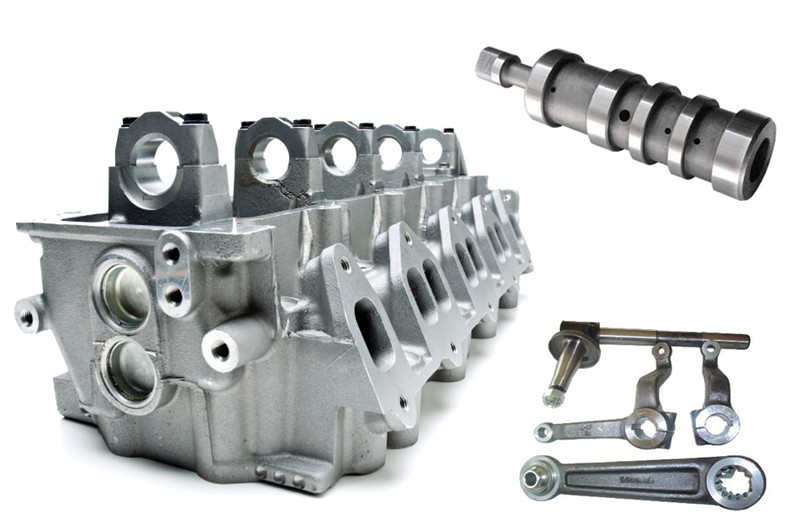

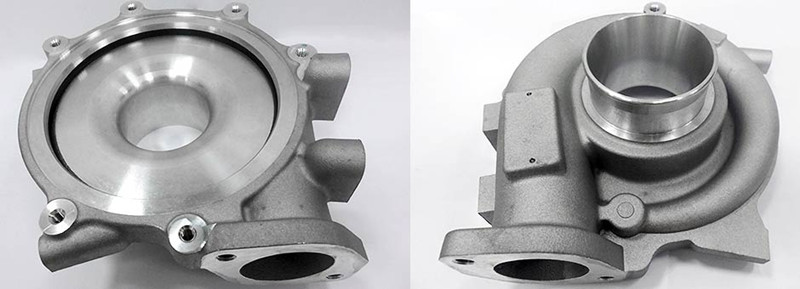

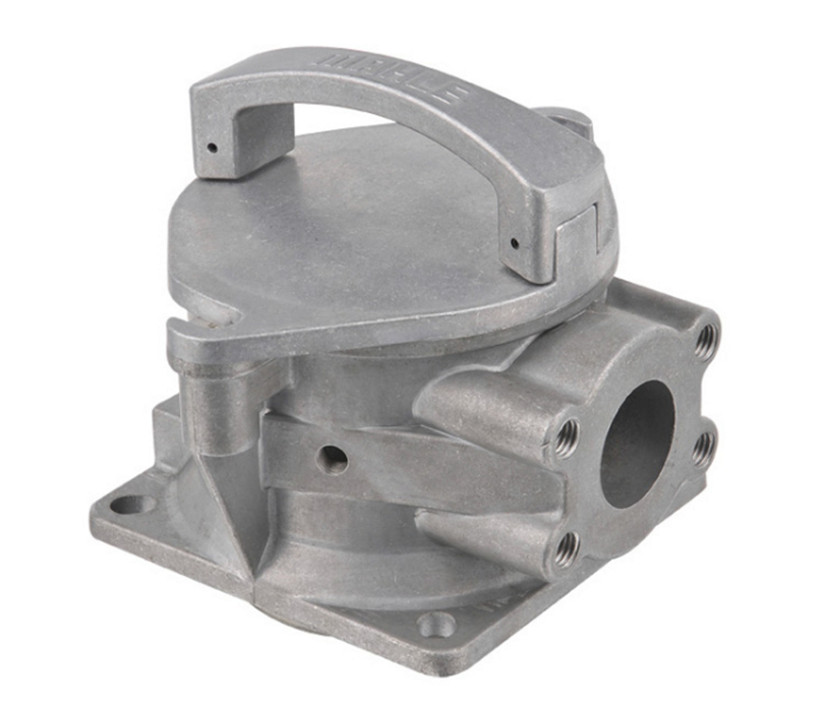

Products show

Product detail pictures:

Related Product Guide:

To continuously increase the administration process by virtue of the rule of sincerely, good religion and excellent are the base of company development, we commonly absorb the essence of linked goods internationally, and continually build new solutions to fulfill the requires of shoppers for Reasonable price Brake Disc - OEM Custom Aluminium Die Casting Part – Mingda , The product will supply to all over the world, such as: Qatar, Manila, Mumbai, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.