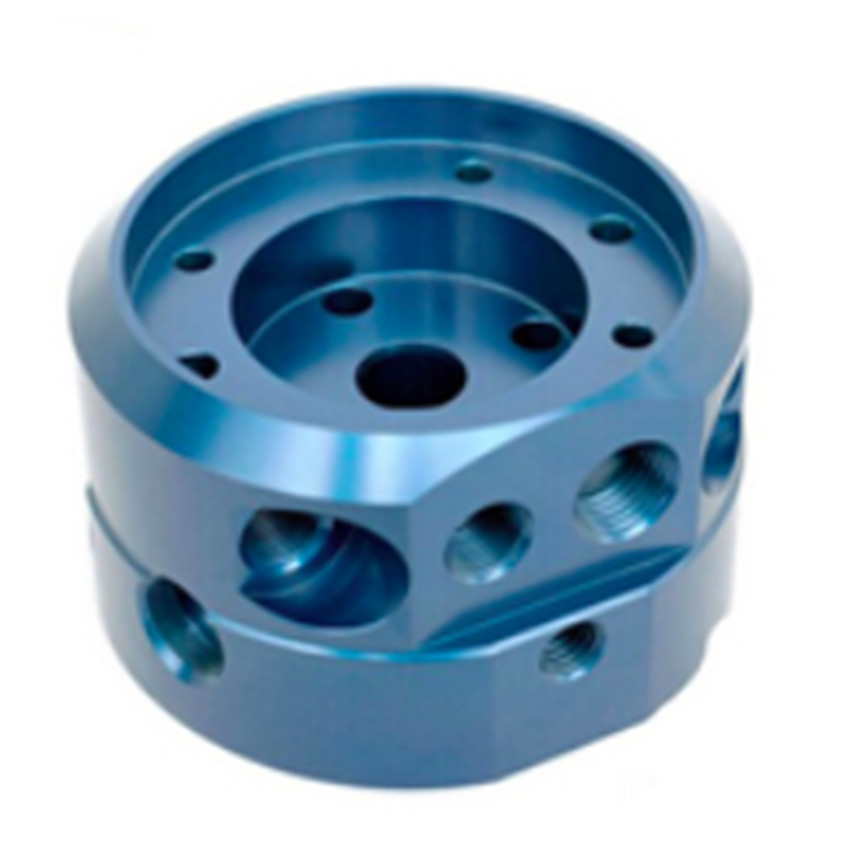

OEM Precision Stainless Steel Component

Product Description

CNC Turning is a machining process similar to milling however the billet which is in the form of a bar, is rotated and the cutting tool is held against the bar to remove the material to your desired shape. Turning is typically suited to cylindrical parts and has a high level of accuracy.

CNC Milling is a machining process that where a cutting tool removes material from a ‘billett’, located on a ‘bed’ in order to produce the desired shape of your part.

CNC Milling is great for producing high quality end-use parts out of metals and plastics.

Specification

Material: Stainless Steel: 303 / 304 / 316(L) / 410 etc.

Dimension: According to the drawing or samples

Processing Equipment : CNC machining center, CNC turning, Grinding machine, CNC Milling machine, Drilling machine etc.

Surface treatment: Polishing, Plating, Anodized, Heat treatment, Inactivation, powder coating etc.

Packing: PE bag, Carton, Wooden box

Samples:Available in 7-20 days for different items

Inspection equipment: CMM (Coordinate measuring machine), Projector, Caliper, Micrometer, Roughness tester, Hardness gauges etc.

Service Items:Product design, production, technical support and after-sales service, mould processing and development etc.

Service: Warm and quick response provided by professional sales team with many years` experience of handling exportation to the US, Europe, Japan and other countries and regions

Products show