OEM Manufacturer Ductile Iron Foundry - Aluminum Die Casting Shell Housing – Mingda

OEM Manufacturer Ductile Iron Foundry - Aluminum Die Casting Shell Housing – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

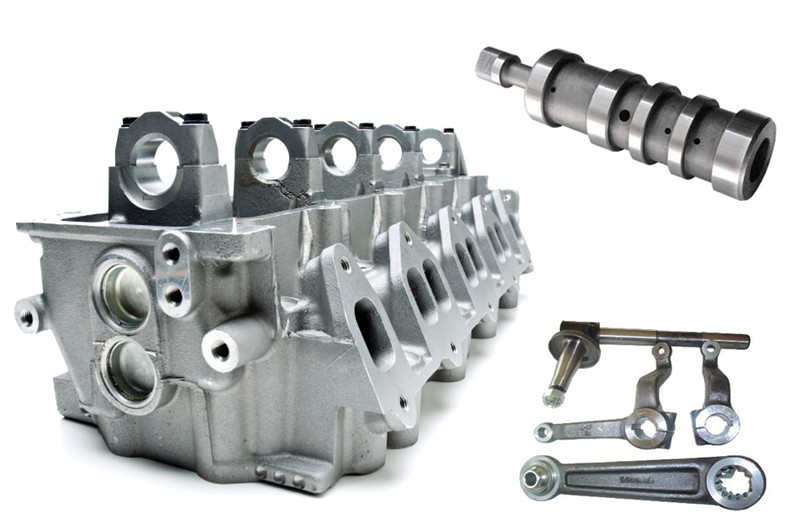

Hebei Mingda provides superior quality aluminum die casting parts and components for a wide range of industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.

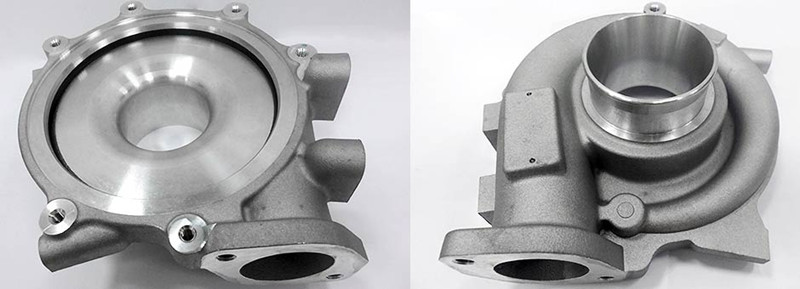

Aluminum die casting is a great choice for manufacturing parts with the highly valued combination of light weight and superior strength at a high rate. With die casting machines ranging from 180 up to 2,000 metric tons and CNC machine centers, we can produce aluminum die casting parts from a few grams to more than 40 pounds with superior quality ready for assembly. For aluminum die casting parts with requirements of esthetical, functional, or protective coatings, we also offer a broad range of surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish.

What Is Aluminum Die Casting?

Aluminum die casting is a manufacturing process for producing accurately dimension, sharply defined, smooth or textured-surface aluminum parts through the use of reusable molds, called dies. The aluminum die casting process involves the use of a furnace, aluminum alloy, die casting machine, and die. Dies that usually constructed with long-lasting, quality steel have at least two sections to permit removal of castings.

Advantages of Aluminum Die Casting

- Simple or complex shapes

- Thin wall thickness

- Light weight

- High rates of production

- Corrosion resistance

- Monolithic – combine multiple functions in one

- Efficient and economical alternative to other processes

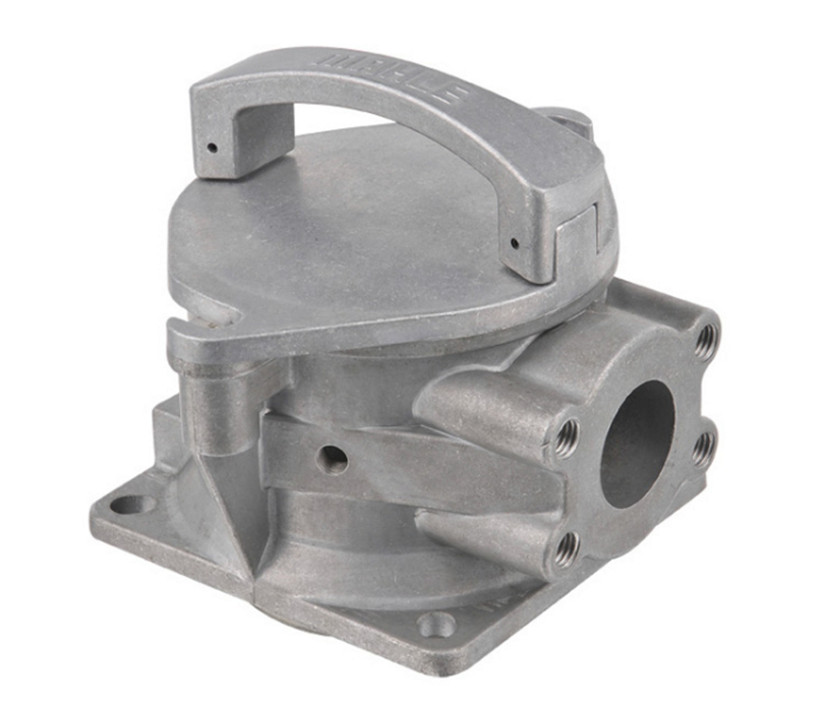

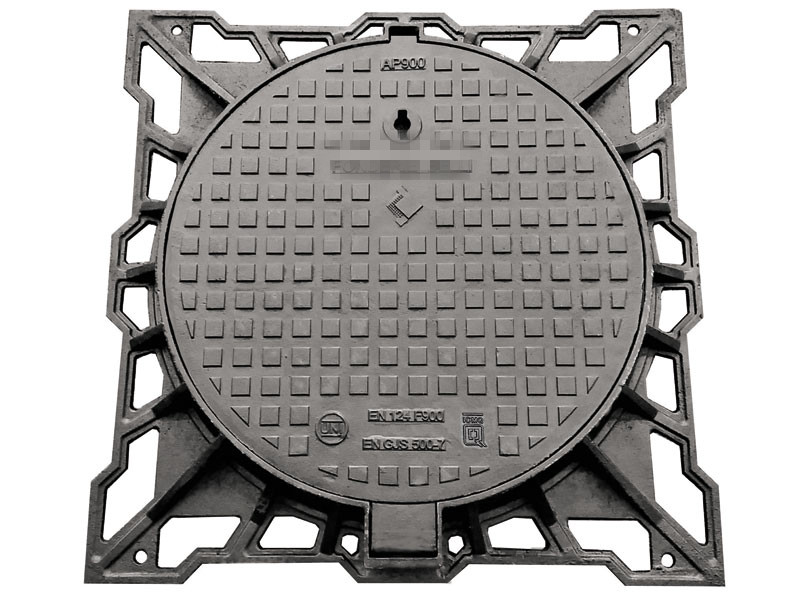

Products show

Product detail pictures:

Related Product Guide:

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for OEM Manufacturer Ductile Iron Foundry - Aluminum Die Casting Shell Housing – Mingda , The product will supply to all over the world, such as: Sweden, Kyrgyzstan, Mozambique, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.