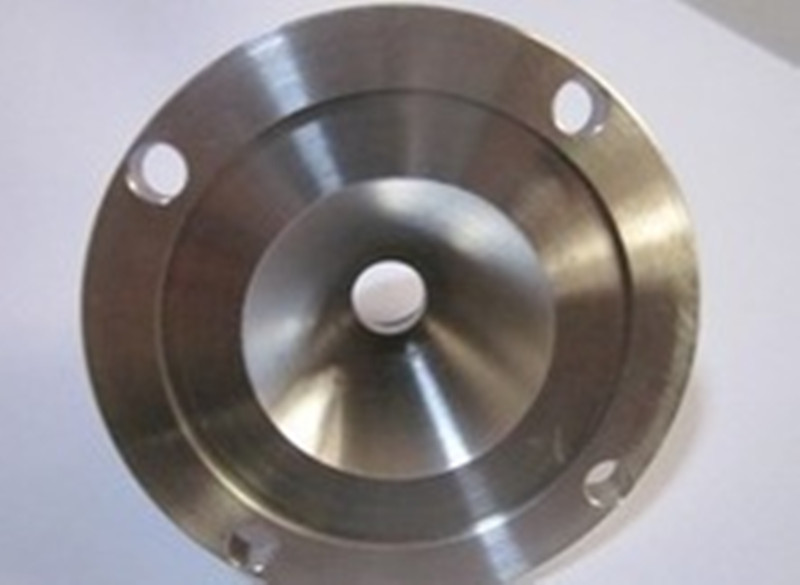

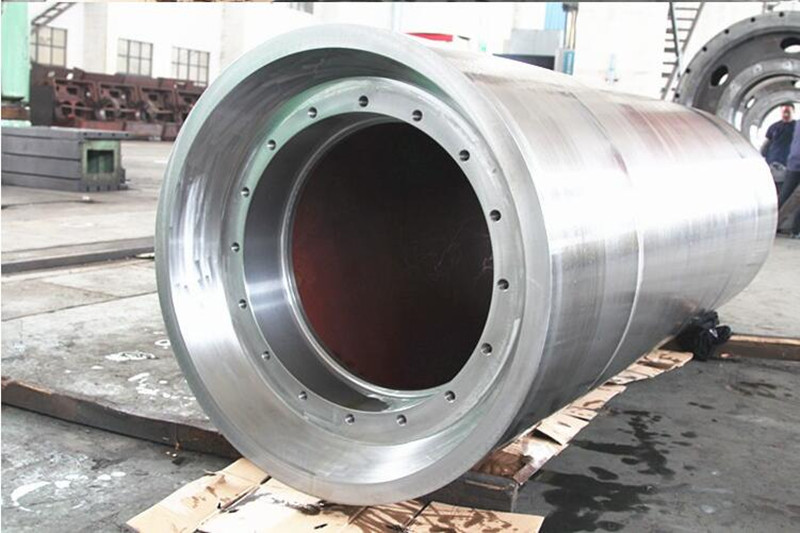

OEM Customized Steel Forging Parts

Product Description

Forging is the process by which metal is heated and is shaped by plastic deformation by suitably applying compressive force. Usually the compressive force is in the form of hammer blows using a power hammer or a press.

Forging refines the grain structure and improves physical properties of the metal. Forgings are consistent from piece to piece, without any of the porosity, voids, inclusions and other defects. Thus, finishing operations such as machining do not expose voids, because there aren’t any. Also coating operations such as plating or painting are straightforward due to a good surface, which needs very little preparation.

Quality control and management to the whole produce process, including ingot smelting, forging, heat treatment, machining and strictly final inspection prior to delivery.

Our service included the forging, process, heat treatment, finish machining, package, local logistics, customers clearance and maritime transport. We took the customer`s requirements as the principal thing, and pay attention on the products quality.