OEM Customized Lost Wax Casting - OEM Custom Brass Casting with CNC Machining – Mingda

OEM Customized Lost Wax Casting - OEM Custom Brass Casting with CNC Machining – Mingda Detail:

Basic Info

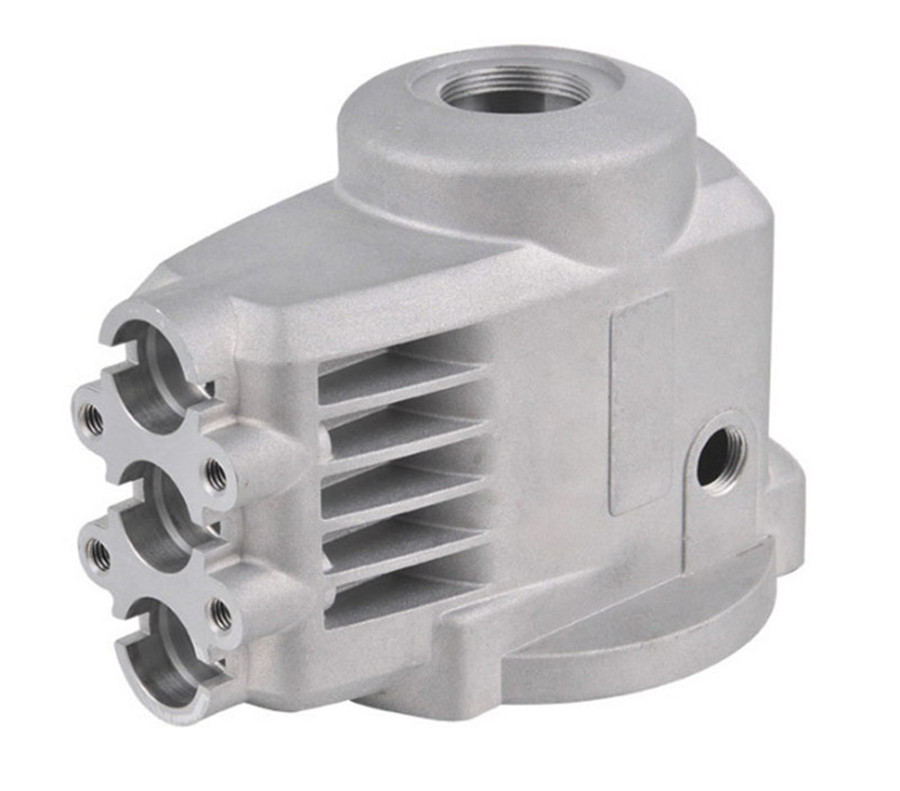

Casting Method: Thermal Gravity Casting

Process: Die Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Metal

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

We provide all kind of Casting work – Metal casting, Brass casting, Aluminium casting, Copper casting, Bronze casting etc. we also provide Stainless Steel Fabrication and Metal Fabrication works which comprises Gates, Grills, Glass and Steel Railing, Fibre shade structure, Shutter, SS Cladding, Table, Wrought casting cast iron, Aluminium Brass Copper Bronze Die casting manufacturers, pre fabricated, Storage Racks and Industrial fabrication works molding bending moulding laser cnc cutting skylight etc. superior quality steel makes these items highly durable and corrosion restive. Stainless Steel Fabrications are available in various designs and style as per the latest trend. We also provide customized design as per the client`s requirement. You can obtain at affordable prices with best quality This new casting method makes possible faster prototype development times, as well as more efficient and cost-effective manufacturing procedures after a part moves to mass production. In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Products show

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for OEM Customized Lost Wax Casting - OEM Custom Brass Casting with CNC Machining – Mingda , The product will supply to all over the world, such as: Vancouver, Iraq, UK, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, most of the merchandise are pollution-free, environmentally friendly solutions, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary products we provide at present, You may also visit our web-site, which involves our most recent product line. We look forward to reactivating our company connection.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!