Manufacturer for Small Metal Stamping Machine - Stainless Steel Metal Stamping Part – Mingda

Manufacturer for Small Metal Stamping Machine - Stainless Steel Metal Stamping Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

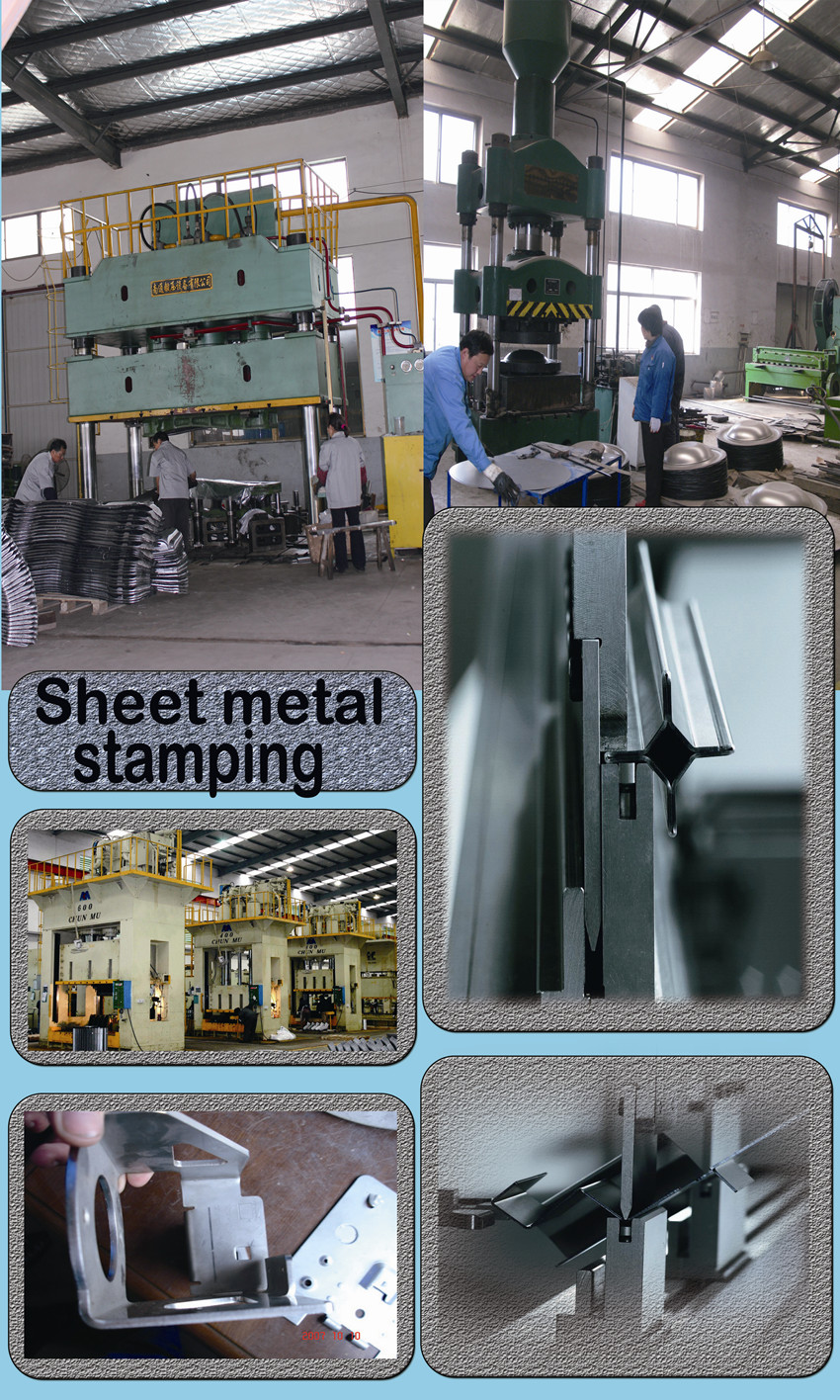

Mingda offer a various of metal forming manufacturing processes,using a single hit and progressive stamping dies.The metal stamping processes including cutting,punching,blanking, embossing, bending, flange, and coining.The thickness range from 0.05 mm to 20 mm thick and our machine size range of 5T~400T.

We can satisfy all your stamping requirements at a competitive price and the highest quality level.

In addition to metal stamping,we can also provide deep drawing,welding-assembly parts,CNC machining parts,extrusion parts etc.

Products show

Product detail pictures:

Related Product Guide:

Now we have superior devices. Our solutions are exported to your USA, the UK and so on, enjoying a superb name between customers for Manufacturer for Small Metal Stamping Machine - Stainless Steel Metal Stamping Part – Mingda , The product will supply to all over the world, such as: Istanbul, Amsterdam, Portugal, We strive for excellence, constant improvement and innovation, is committed to make us the customer trust and the first choice of engineering machinery accessories brand suppliers. Choose us, sharing a win-win situation!

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.