Manufacturer for Hydrant Pipes - OEM Silica Sol Investment Casting Part – Mingda

Manufacturer for Hydrant Pipes - OEM Silica Sol Investment Casting Part – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

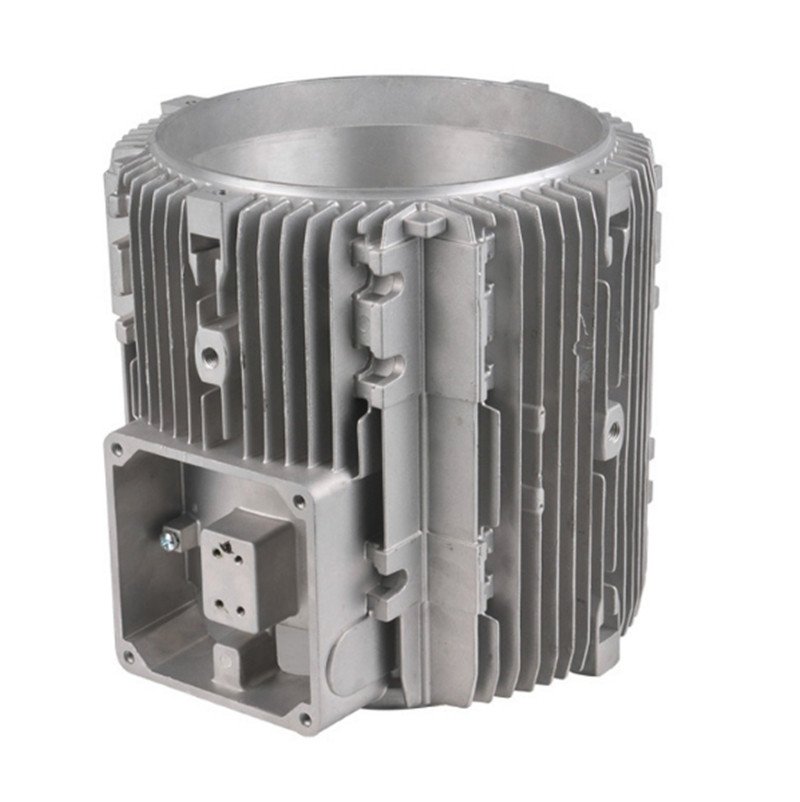

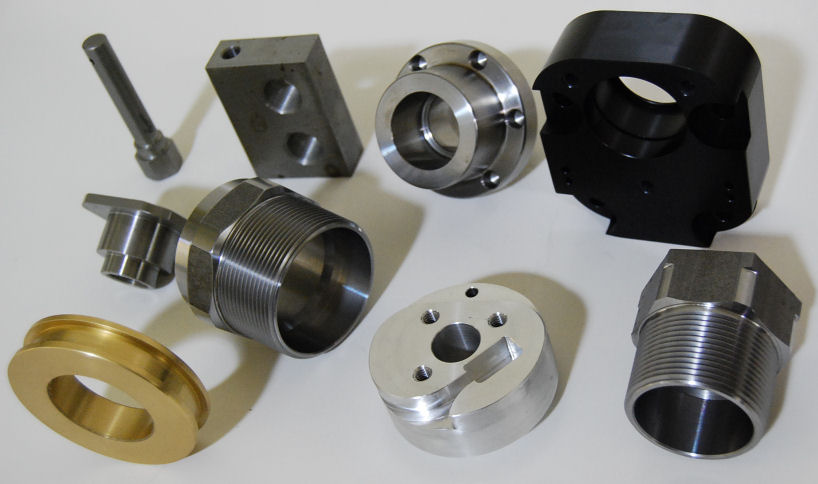

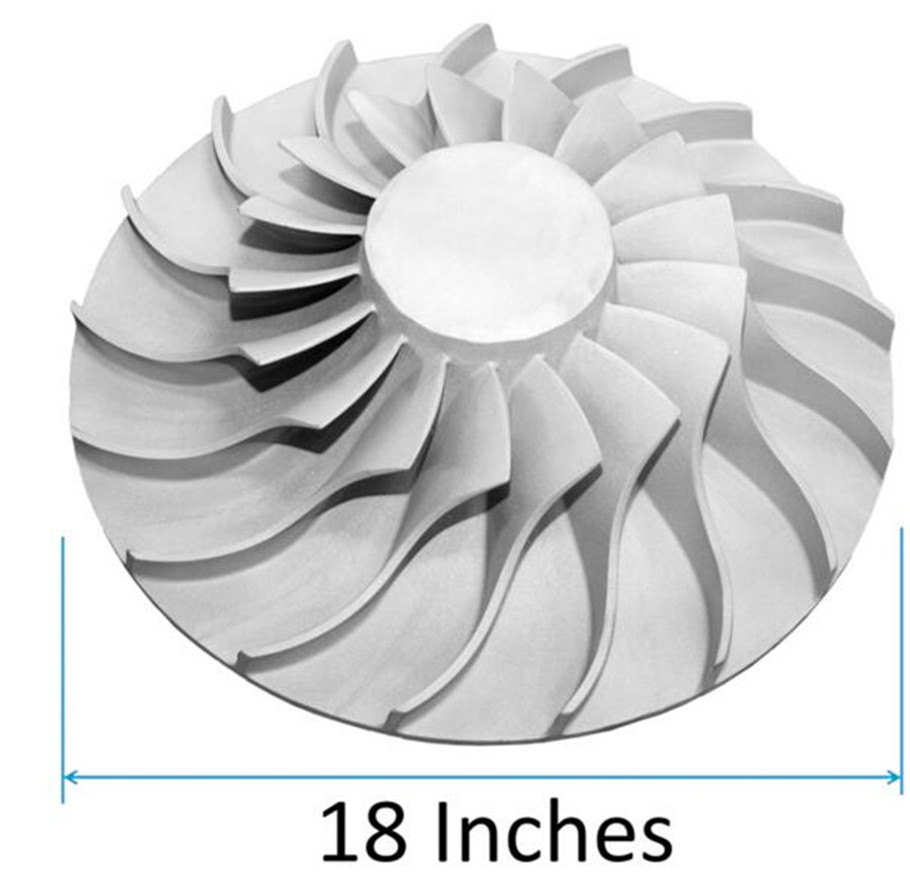

The investment casting process or lost wax process, can produce the most intricate shapes in just about any alloy. In order to produce & machine these parts, you need to have in depth knowledge of the alloys and much experience…both of which Thompson Investment Casting possesses. There is no other metal working process that provides the design freedom to easily cast complex intricate shapes and assemblies as the investment casting process. The lost wax method out performs any other casting process when it comes to superior surface finishes especially when compared to sand casted, forged or welded fabrications. Some specific benefits are:

Reliability

The investment casting process provides reliable process controls and repeatability that are maintained from casting to casting.

Tolerances

Hebei Mingda routinely holds to tolerances of ± .005″. This is not always possible with other types of casting processes.

Amortization Lowers Tooling Cost

The initial wax injection mold to produce the patterns, averaged over the entire production quantity, is often lower than other casting tooling costs. Quality tooling produces a quality part and will be more cost efficient in the long run.

Intricate Design

When using investment castings, design engineers can easily incorporate features such as logos, product ID’s/numbers, and letters into their component. Thru holes, slots, blind holes, external and internal splines, gears, and thread profiles can often be cast to reduce secondary machining time and total part cost.

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for Manufacturer for Hydrant Pipes - OEM Silica Sol Investment Casting Part – Mingda , The product will supply to all over the world, such as: Danish, Malta, Korea, Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

With a positive attitude of regard the market, regard the custom, regard the science, the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.