Hot New Products Hydrants - OEM Custom Lost Wax Stainless Steel Casting – Mingda

Hot New Products Hydrants - OEM Custom Lost Wax Stainless Steel Casting – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Investment casting or `lost wax casting` provides a shortcut to your finished precision parts without welding, excessive machining, or assembly. It is the solution for many complex shapes and provides smooth surface finishes, accurate dimensions and fine detail. Spectron Manufacturing`s advanced tools, technology, and skilled technicians make certain that all investment cast parts address our customers` demands as well as all applicable industry standards.

- Furnace capacity includes three steel and two aluminum melting units, two ovens for wax burnout (lost wax process) from the ceramic mold and four ovens for preheating ceramic shells.

- Manufacturing enterprise resource planning (MRP/ERP) software provides unparalleled coverage of, and access to, operational intelligence allowing continuous improvement, accountability, quality, and transparency throughout the investment casting process.

- Non-destructive Testing (NDT) including magnetic particle inspection, dye penetrant inspection, and digital X-ray is conducted in-house for tight control and quick identification of potential issues.

- Secondary finishing services including machining, coatings and managing sub-assembly. View all Secondary Operationscapabilities.

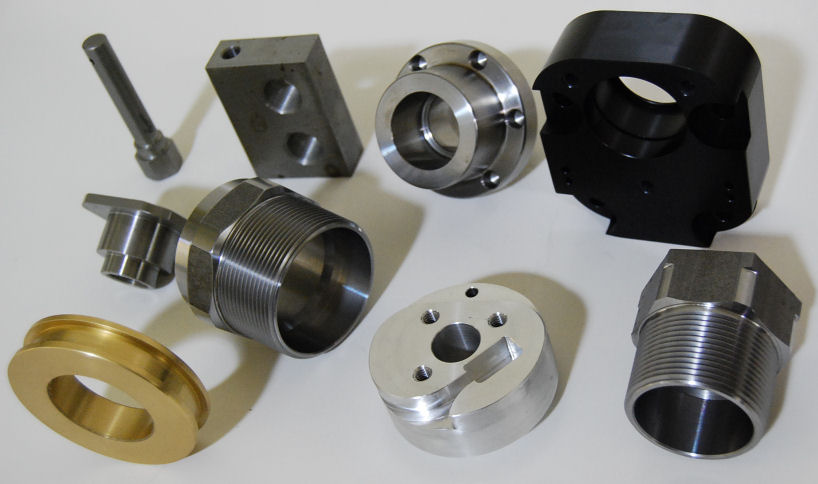

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

We'll make every effort and hard work being outstanding and excellent, and speed up our techniques for standing during the rank of global top-grade and high-tech enterprises for Hot New Products Hydrants - OEM Custom Lost Wax Stainless Steel Casting – Mingda , The product will supply to all over the world, such as: Mozambique, Slovakia, Accra, Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!