High Quality Metal Stamping Parts - Sheet Metal Punching and Stamping Part – Mingda

High Quality Metal Stamping Parts - Sheet Metal Punching and Stamping Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Stamping are the production technology of product parts with certain shape, size and performance by means of the power of conventional or special stamping equipment so that the sheet material is directly deformed and deformed in the mold. Sheet metal, mold and equipment are three elements of stamping. Stamping is a metal cold deformation processing methods. Therefore, it is called cold stamping or sheet stamping, referred to as stamping. It is one of the main methods of metal plastic processing (or pressure processing), and it is also affiliated with material forming engineering technology.

Of the global steel products, 50 to 60% are made of sheet metal, most of which are pressed and pressed into finished products. The body of the car, the radiator plate, the steam drum of the boiler, the shell of the container, the core steel of the motor and the electric appliance, etc. are all stamped and processed. There are also a large number of stamping parts in products such as instrumentation, household appliances, office machines, and storage containers. Stamping is a highly efficient move to take complex model, the exception is a multi-position progressive die, in a press to complete multi-channel stamping operation, complete the automatic generation of materials. Generate fast, long rest time, Linqu low cost, the collective Linqu hundreds of pieces per minute, by many processing plant favorite.

Stamping parts and castings and forgings are strong and have thin, uniform, light and strong characteristics. Stamping can produce work pieces with reinforcing ribs, ribs, coils, or flange that are difficult to manufacture with this mature handpath to increase its rigidity. Due to the rejection of rough molds, the accuracy of the work piece can reach micrometers, and the accuracy and specifications are the same. The holes and bosses can be punched out. In actual production, commonly used and stamping process similar to the test, such as drawing performance test, bulging performance test materials such as stamping performance test to ensure the quality of finished products and high pass rate.

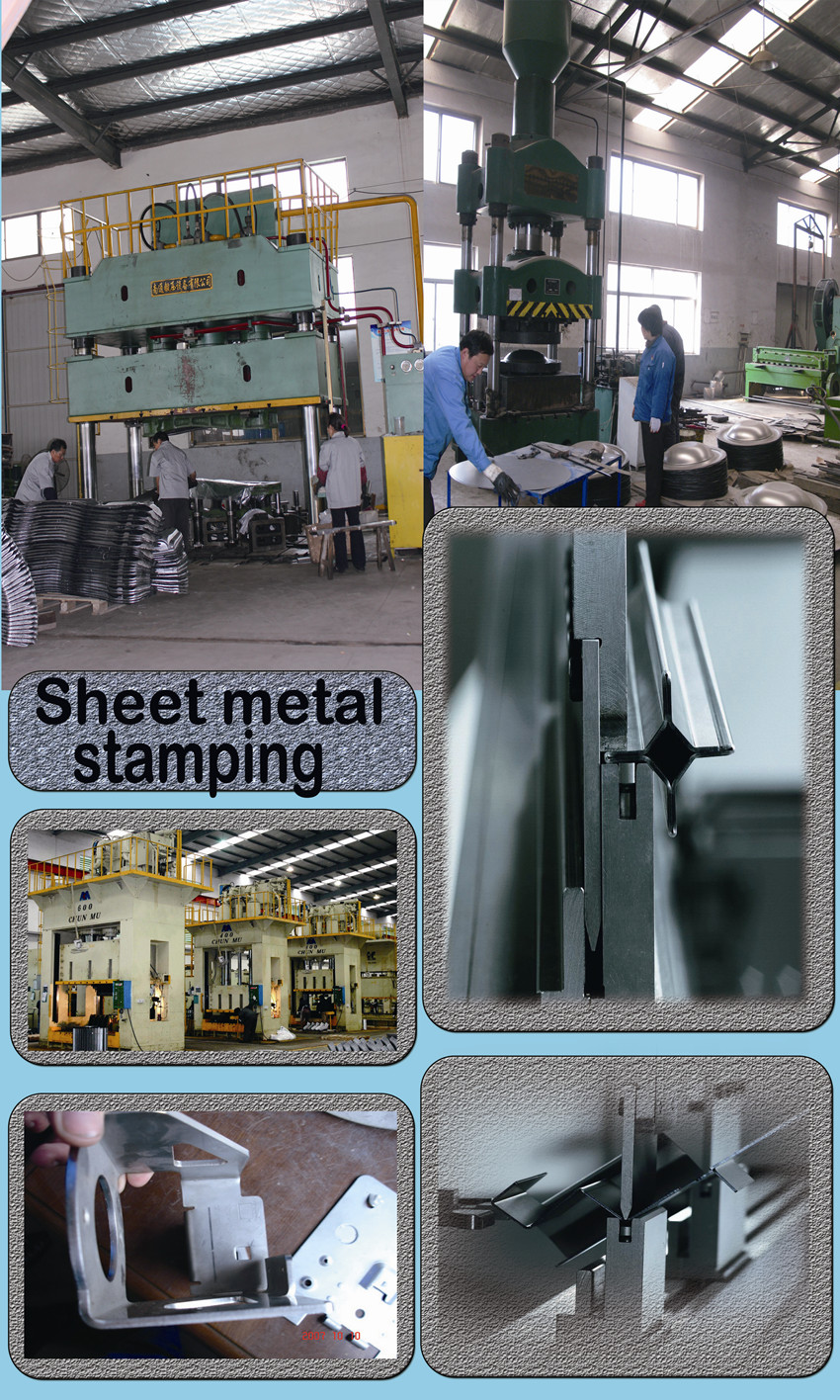

Products show

Product detail pictures:

Related Product Guide:

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for High Quality Metal Stamping Parts - Sheet Metal Punching and Stamping Part – Mingda , The product will supply to all over the world, such as: British, Denver, Sao Paulo, All the employees in factory, store, and office are struggling for one common goal to provide better quality and service. Real business is to get win-win situation. We would like to provide more support for customers. Welcome all nice buyers to communicate details of our products with us!

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.