Good Wholesale Vendors Lost Wax Casting Stainless Steel – OEM Custom Zinc Die Casting – Mingda

Good Wholesale Vendors Lost Wax Casting Stainless Steel – OEM Custom Zinc Die Casting – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

We produce zinc die casting parts from a few grams to more than 100 pounds with superior quality ready for assembly. we offer a broad range of zinc die casting surface finishing including powder coating, e-coating, shot blasting, chrome plating, and bright finish. The industries include automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical, energy, aerospace, submarine and others.

What Is Zinc Die Casting?

Zinc die casting is a metal casting process characterized by pressuring molten metal into the mold cavity. The mold cavity is created using two hardened tool steel molds that are machined to the net shape or near net shape of the zinc die casting parts. Zinc die casting process allows products to be made with high degree of accuracy and repeatability. The Zinc die casting process can also produce fine details such as textured surfaces or names without requiring further processing.

Advantages of Zinc Die Casting

- Great tool life

- Precision tolerance

- Superior thermal conductivity

- Fast cycle time

- Corrosion resistance

- Superior for decorative finishing

- Low energy cost

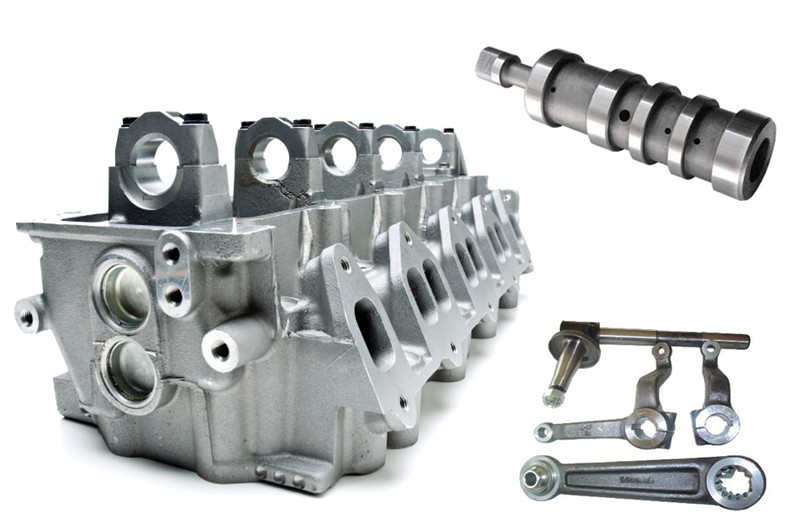

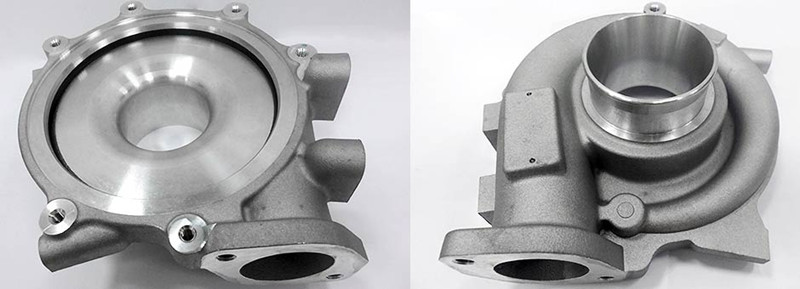

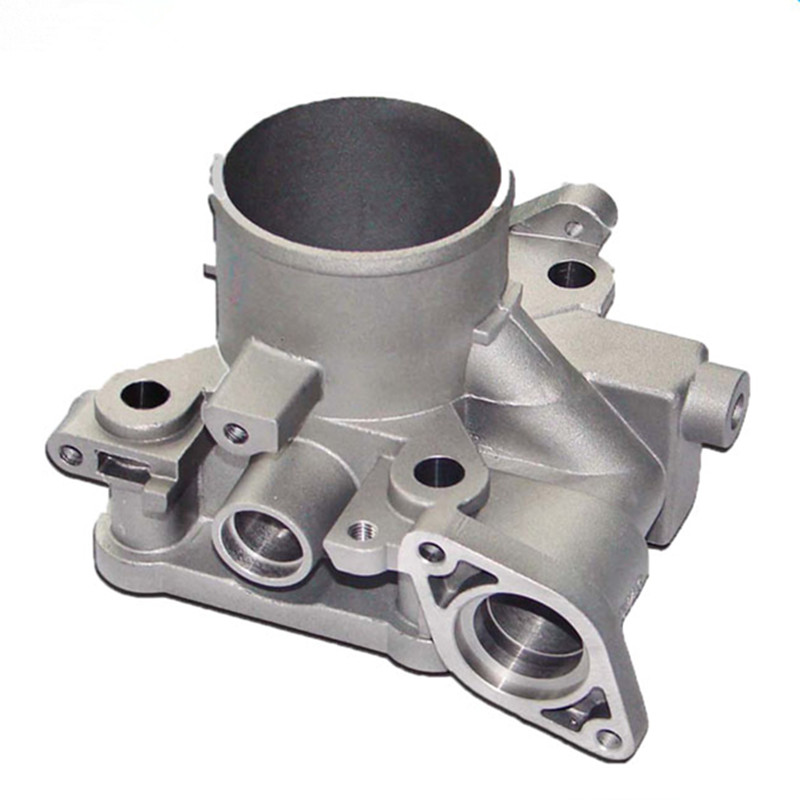

Products show

Product detail pictures:

Related Product Guide:

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for Good Wholesale Vendors Lost Wax Casting Stainless Steel – OEM Custom Zinc Die Casting – Mingda , The product will supply to all over the world, such as: Juventus, Indonesia, Nepal, we are sincerely hope to establish one good long term business relationship with your esteemed company thought this opportunity, based on equal, mutual beneficial and win win business from now till the future.

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,