Free sample for Lost Foam Casting - OEM Custom Alloy Steel Casting Parts – Mingda

Free sample for Lost Foam Casting - OEM Custom Alloy Steel Casting Parts – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Take your casting solutions to a whole new level with our lost wax investment castings. Investment castings are often known as lost wax casting, silica sol casting, precise casting or de-waxing casting, the materials used for casting process are vary widely.

The great part about casting is that there is no limit to product shape, size or structure, according to your unique, custom specifications. Investment casting is well known for lower machining allowance, closer tolerance control and better surface finish, which makes it very popular. Additionally, these castings are known to be of superior quality, making them highly in demand in the industry today.

We handle large or small orders and you need not worry about the quality of the finished product.

Stainless steel: 303/304/316/duplex2205/17-4PH/4340/ect

We handle many other type of materials.Please contact us if your required materials are not listed above.

Technology: precision casting, investment casting,silica sol casting,water glass casting

Surface treatment: Blacking, Polishing, Anodize, Chrome plating, Zinc plating,Nickel plating, Tinting, Power coating, E-coating etc

Professional precision manufacture for more than 13 years.

Molding process–Precision Casting

Material:– Carbon steel Alloy steel,stainless steel duplex2205,Standard:DIN ASTM

Possible Heat Treatment–Normalizing, tempering, hardening and tempering

Industry involved– pump&construction&Agricultural& Engineering& Automotive industry–..

Part Unit Weight range–0.01Kg~160kg

Wall thickness requirements–min 2mm

Manufacturer certification– ISO9001 (2008) TS16949:2009

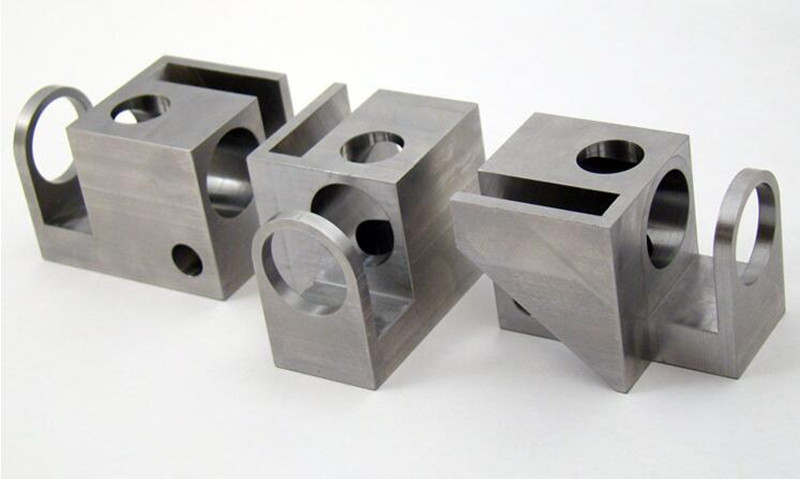

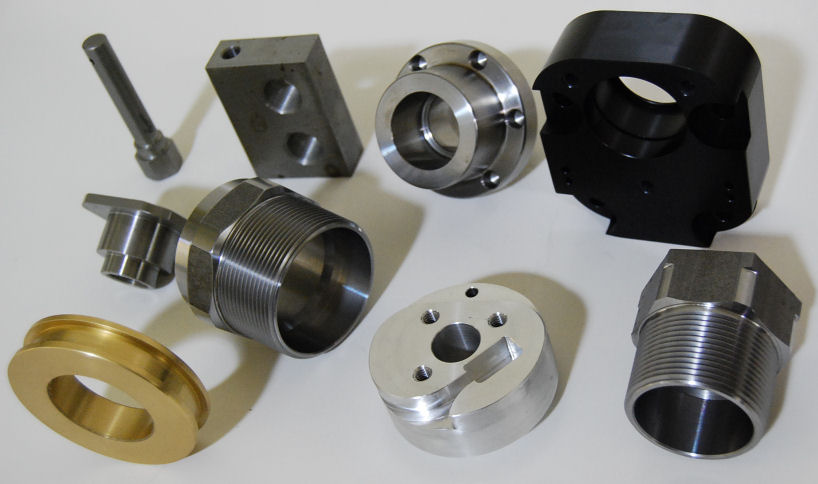

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for Free sample for Lost Foam Casting - OEM Custom Alloy Steel Casting Parts – Mingda , The product will supply to all over the world, such as: Somalia, Sacramento, Macedonia, Our company always concentrate on the development of the international market. We now have a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.