Factory wholesale Bronze Castings - Zinc Alloy/ Aluminum Sand Casting – Mingda

Factory wholesale Bronze Castings - Zinc Alloy/ Aluminum Sand Casting – Mingda Detail:

Basic Info

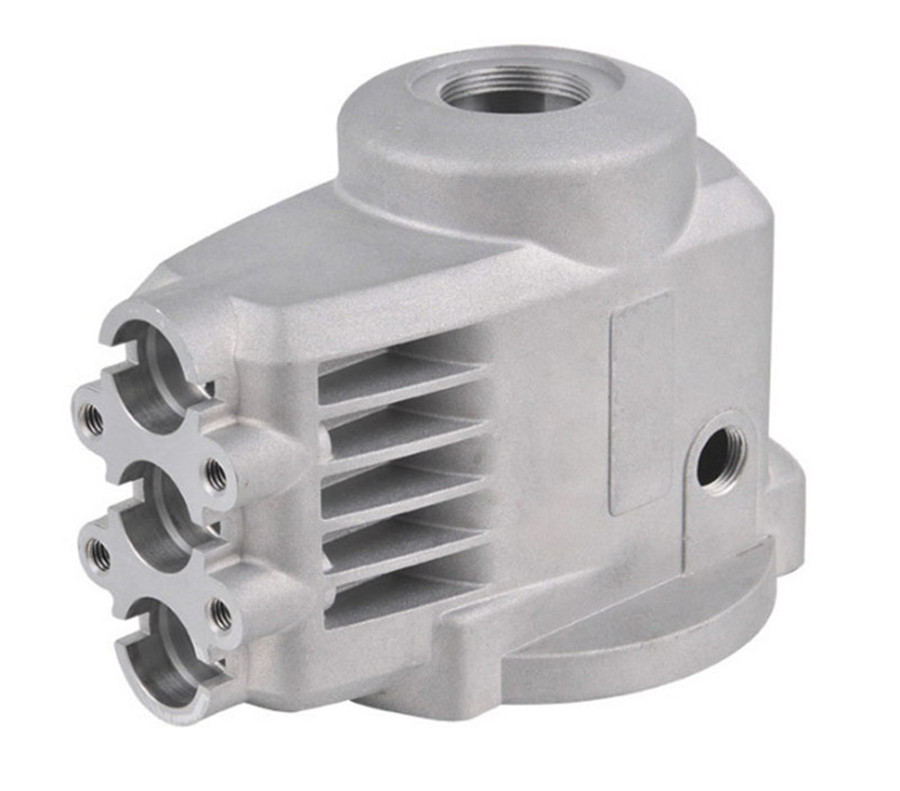

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 7

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

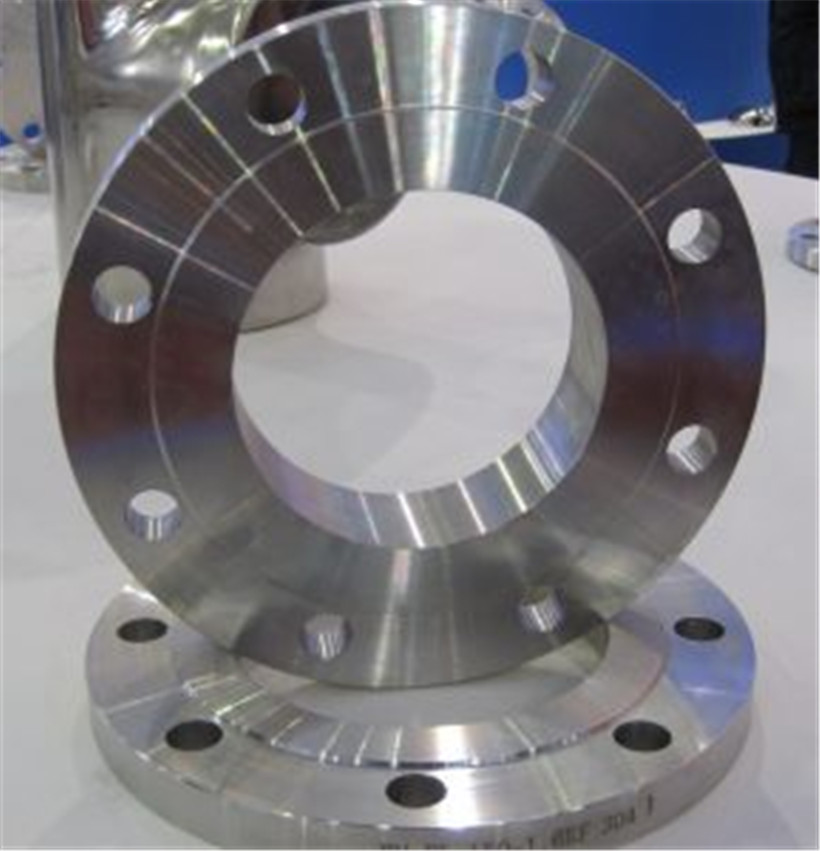

We specialize in very complex, close tolerance aluminum sand castings. Primary alloys include aluminum silicon (300 series) and aluminum-magnesium (500 series). All electric melting. Four hunter automatic, Green Sand Molding lines are used for high to medium volume parts from ounces to 50 pounds. Low volume and prototypes castings up to 40 pounds are produced on our Airset/Nobake molding line. We also are capable of providing prototype castings.

Sand casting is an efficient metal casting process in which sand is used as the mould material. Over 70% of the world`s metal castings are produced via the sand casting process, and Harrison Castings have the largest sand casting foundry in the UK. The two most common types of aluminium sand castings processes are Green Sand Casting and the Air Set Casting method. We moved away from the traditional Green Sand moulding method in the early 1990s in favour of Air Set moulding Casting in sand is a highly efficient and cost-effective process because up to 80% of the moulding sand we used is reclaimed and reused. This streamlines our manufacturing process whilst greatly reducing the cost and amount of waste produced. The sheer strength of the moulds created means that a much greater weight of metal can be used, allowing for the casting of complex components that might otherwise have been fabricated from individual parts. Moulds can be created for a lower initial setup cost compared to aluminium gravity die casting and other casting methods.

What Is Sand Casting?

Why Use Sand Casting Over Other Casting Methods?

Product detail pictures:

Related Product Guide:

While in the past few years, our organization absorbed and digested innovative technologies both equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted for the advancement of Factory wholesale Bronze Castings - Zinc Alloy/ Aluminum Sand Casting – Mingda , The product will supply to all over the world, such as: Ukraine, kazakhstan, Roman, Good quality and reasonable price are our business principles. If you are interested in our products or have any questions, please feel free to contact us. We hope to establish cooperative relationships with you in the near future.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!