China wholesale Deep Draw Metal Stamping - OEM Custom Stainless Steel Metal Stamping – Mingda

China wholesale Deep Draw Metal Stamping - OEM Custom Stainless Steel Metal Stamping – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

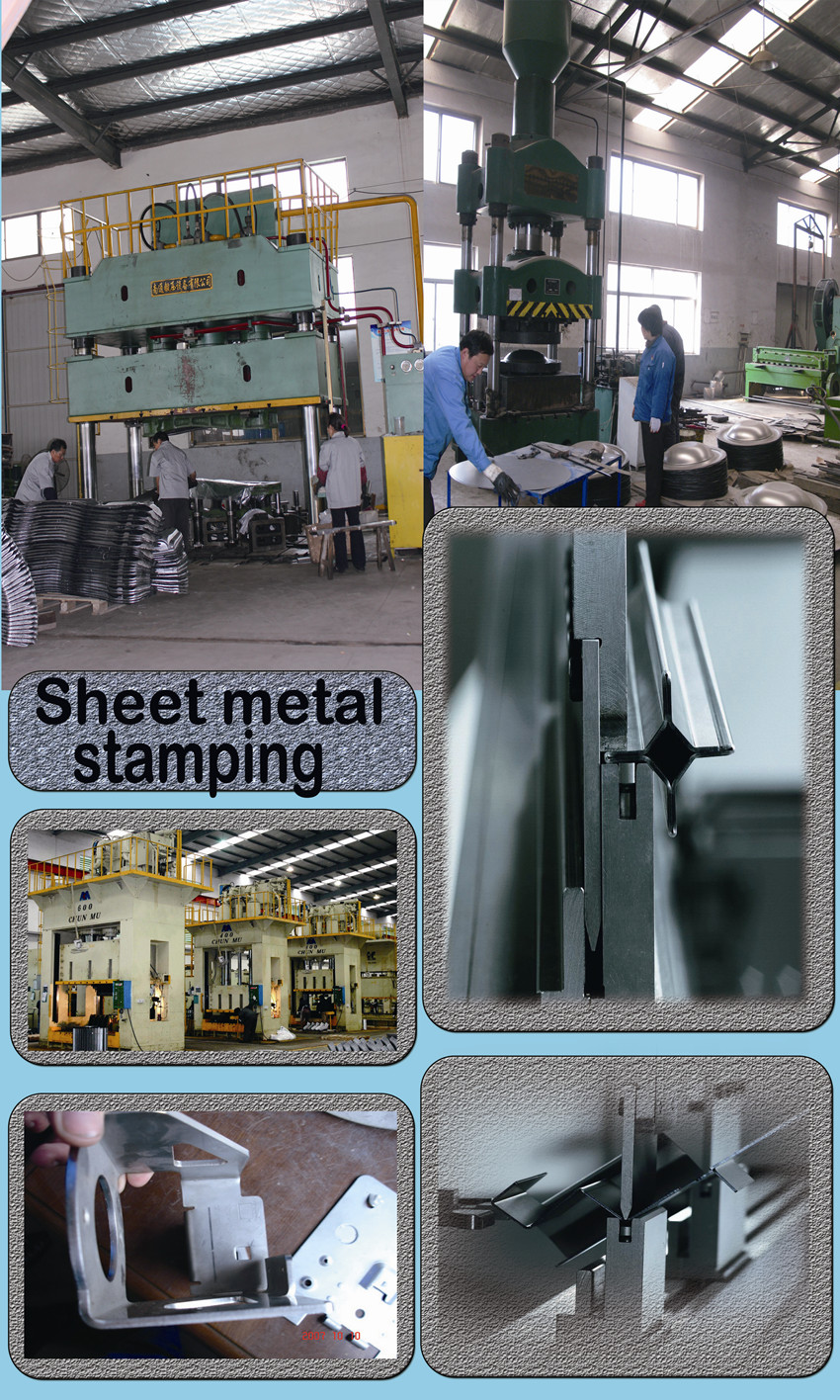

Hebei Mingda International Trading Co.,Ltd is pleased to provide precision metal stamping services, offering prototyping, production runs, and contract manufacturing of custom stampings. We employ the latest equipment and production methods, carrying out complex stamping operations with progressive, transfer, and compound dies. We are experienced in coining, compression, deep drawn, high speed, robotic, continuous strip, multi slide, and fully sheared production methods among others. On site equipment boasts a press rating up to 450 tons, press speeds from 50 to 450 cycles/minute, maximum feed rate of 12 in/sec and a 9″ maximum press stroke.

Parts are stamped from a wide range of materials including steel, aluminum, stainless steel, nickel sheet, beryllium copper, copper, brass, Kovar, titanium, and exotics. Components are possible from .25″ to 240″ in length, up to 12″ in width, .250″ in thickness, and up to 12″ in diameter. Projects are executed holding tight tolerances of ± 0.0005″. The highest quality levels are maintained with our ISO 9001:2008 certified quality assurance protocols including go/no go gauges, ring gauges, plug gauges, and optical inspections; SPC methodology, lot traceable process, and full documentation. For more information on our precision metal stamping services or the host of value added products and services please see the table below or contact us directly.

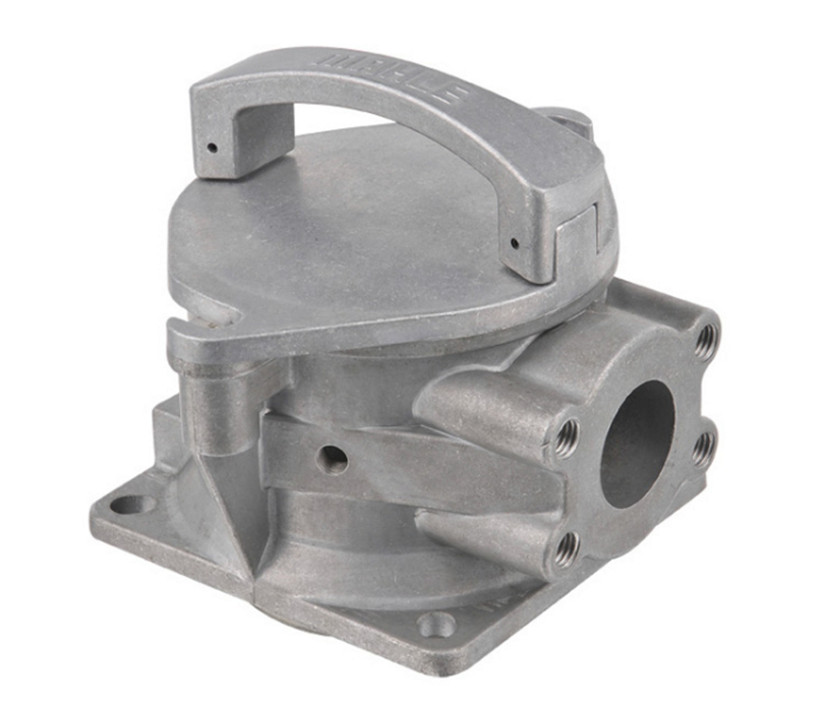

Products show

Product detail pictures:

Related Product Guide:

With our loaded practical experience and thoughtful solutions, we now have been identified for a trusted provider for numerous intercontinental consumers for China wholesale Deep Draw Metal Stamping - OEM Custom Stainless Steel Metal Stamping – Mingda , The product will supply to all over the world, such as: Tunisia, Johor, New Zealand, You can always find the solutions you have to have in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We have been looking forward to work with you for a win-win situation.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.