Bottom price Iron Shell Sand Moulding - Stainless Steel Investment Casting for Auto Part – Mingda

Bottom price Iron Shell Sand Moulding - Stainless Steel Investment Casting for Auto Part – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Investment Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra3.2

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

The main advantage of cast steel is the design flexibility. The designer of the casting has the greatest freedom of design choices. This allows for complex shapes and hollow cross-section parts.The weight range of steel castings is larger. Little weight can be only a few dozen grams of molten mold precision castings. The weight of large steel castings goes up to several tons, dozens of tons or hundreds of tons.Steel castings can be used for a variety of working conditions. Its mechanical properties are superior to any other casting alloys, and a variety of high-alloy steel for special purposes. To withstand high tensile stress or dynamic load of components, it is important to consider pressure vessel castings. In low or high temperature, large and important part load key parts should give priority to steel castings.

Product description

Process : Investment Casting

Material: Stainless Steel,Carbon Steel,Alloy Steel,etc

Weight: 0.001Kg~30Kg

Heat Treatment: Anneal,Quenching,Normalizing,Carburizing,Polishing,Plating, Painting,etc

Machining Equipment : CNC Center , CNC Machines, Turning Machines,Drilling Machines , Milling Machines, Grinding Machines,etc

Measuring Tool : CMM , Projector, Vernier Caliper, Depth Caliper, Micrometer,Pin Gauge, Thread Gauge , Height Gauge,etc

QC System: 100% Inspection Before Shipment

Application: Nail Gun Parts,Mining Drilling Bit,Lock Parts,Sew Machine Part,Hardwares,etc

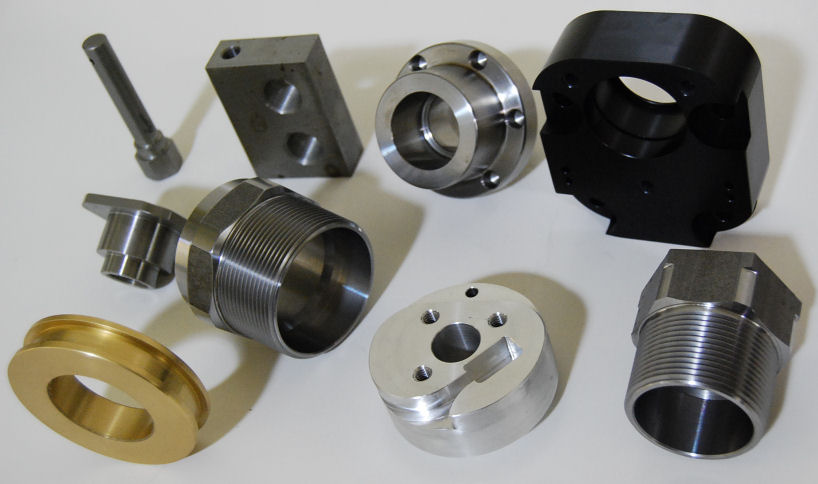

Products show

Product detail pictures:

Related Product Guide:

It really is a good way to further improve our goods and service. Our mission would be to acquire inventive items to buyers with a very good encounter for Bottom price Iron Shell Sand Moulding - Stainless Steel Investment Casting for Auto Part – Mingda , The product will supply to all over the world, such as: Albania, Vietnam, belarus, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.