Bottom price Iron Shell Sand Moulding - OEM Custom Carbon Steel Precision Casting Parts – Mingda

Bottom price Iron Shell Sand Moulding - OEM Custom Carbon Steel Precision Casting Parts – Mingda Detail:

Basic Info

Casting Method: Thermal Gravity Casting

Process: Lost Wax Casting

Molding Technics: Pressure Casting

Application: Machinery Parts

Material: Stainless Steel

Surface Preparation: Polishing

Surface Roughness: Ra6.3

Machining Tolerance: +/-0.01mm

Standard: AISI

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 10 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Carbon steel is a popular material for a wide range of applications. It is inexpensive, readily available in numerous grades, and can be heat-treated to improve its strength, ductility, and machinability.

As one of the industry`s leading metal casting companies, Hebei Mingda pours a variety of carbon steel alloys. We can provide custom carbon steel investment castings that meet your unique specifications. Our investment casting capabilities enable us to achieve tight tolerances and outstanding part to part repeatability, whether your parts weigh just a few ounces or 100+ pounds.

Carbon and Low Alloy Grades:

1018-1020-1025-1030-1041-1045-1050-1141

4130-4140-4150-4340

6150-8615-8620-8630-52100

Carbon steel investment castings are commonly used in a broad spectrum of industries. Mining, hardware and locks, military and firearms, transportation, and many other industrial markets utilize cast carbon steel parts and components in their daily operations.

Request a quote today on carbon steel investment castings, or contact us for more information.

Description:

Carbon steel precision casting parts

Submersible pump front-end parts

1. Material: 45C steel

2. Processing: lost was casting.

3. Finish: sand blasting, anti-rust oil treatment.

4. Application Industry : pump.

5. Equipments: IF furnace, casting wax machine production line, Shell automatic production line, casting production line, heat treatment furnace, spectrum analyzer, universal testing machine, metallographic microscope, hardness tester, X-ray diffractometer

6. Certificates:ISO9001:2015

7. Implementation Standard: ISO, JIS, AISI, DIN, ANSI

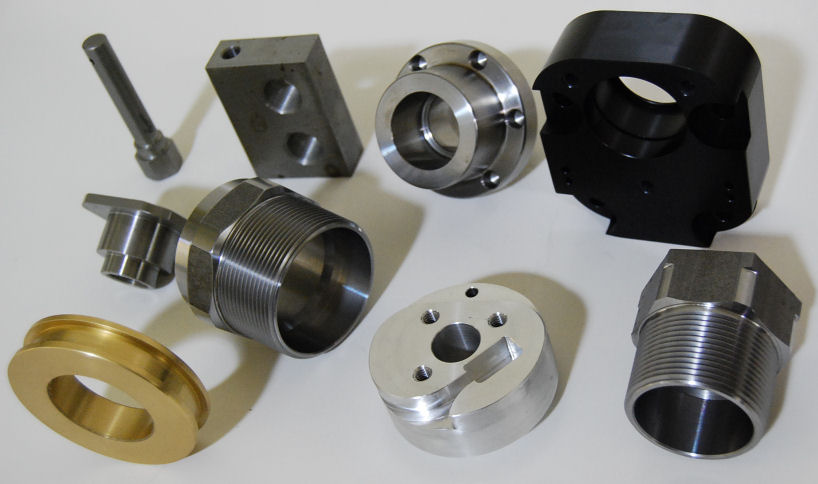

Products show

Process

Our factory

Product detail pictures:

Related Product Guide:

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Bottom price Iron Shell Sand Moulding - OEM Custom Carbon Steel Precision Casting Parts – Mingda , The product will supply to all over the world, such as: America, Algeria, Paraguay, With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the best, but we are trying our best to be your good partner.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.