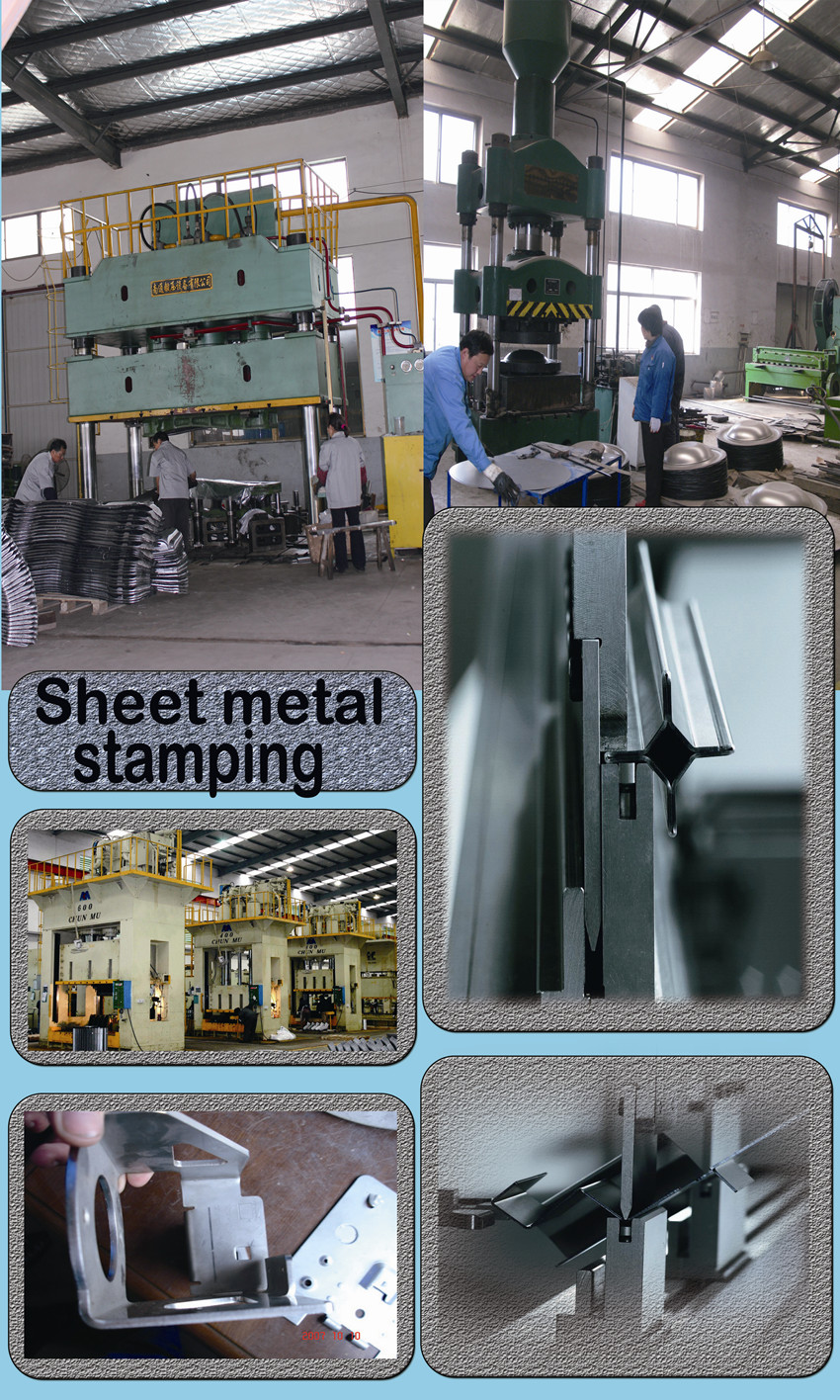

2019 Good Quality Sheet Metal Stamping Parts - OEM Custom Precision Steel Stamping Part – Mingda

2019 Good Quality Sheet Metal Stamping Parts - OEM Custom Precision Steel Stamping Part – Mingda Detail:

Basic Info

Type: Cold Stamping

Processing Type: Shaping Metal

Material: Stainless Steel

Mould: Multistep Progressive Dies

Surface Processing: Electroplating

Fine Blanking: Open

Process: Forming Process

Industry: Metal Stamping Parts

Tolerances: 0.01mm

Customized: Customized

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Hebei Mingda custom metal stamping services deliver precision metal stampings from prototype through production quantities. We run stampings up to .188″ thick, but our specialty is high-volume, tight tolerance, precision stampings in a variety of materials from .003″-.060″ thick. Our presses have full feed lines and are die sensor protection ready. We run nearly 60 million stampings per year at a 98% on time delivery rate.

Our production stamping methods include progressive and single hit dies, using materials such as aluminum, brass, copper, bronze, carbon, stainless steels and exotic metals. We have expertise in deep draw, mandrel, blanking, cam dies, transfer, louvering, insertion and rolled seam dies, among others. Our press capabilities range from 30 to 200 tons. Parts are fully inspected using vision systems, optical comparators, CMM equipment and functional gages. Mingda serves industries including aerospace, defense, medical and electronics, for applications such as heat transfer products, military components and electronic assemblies.

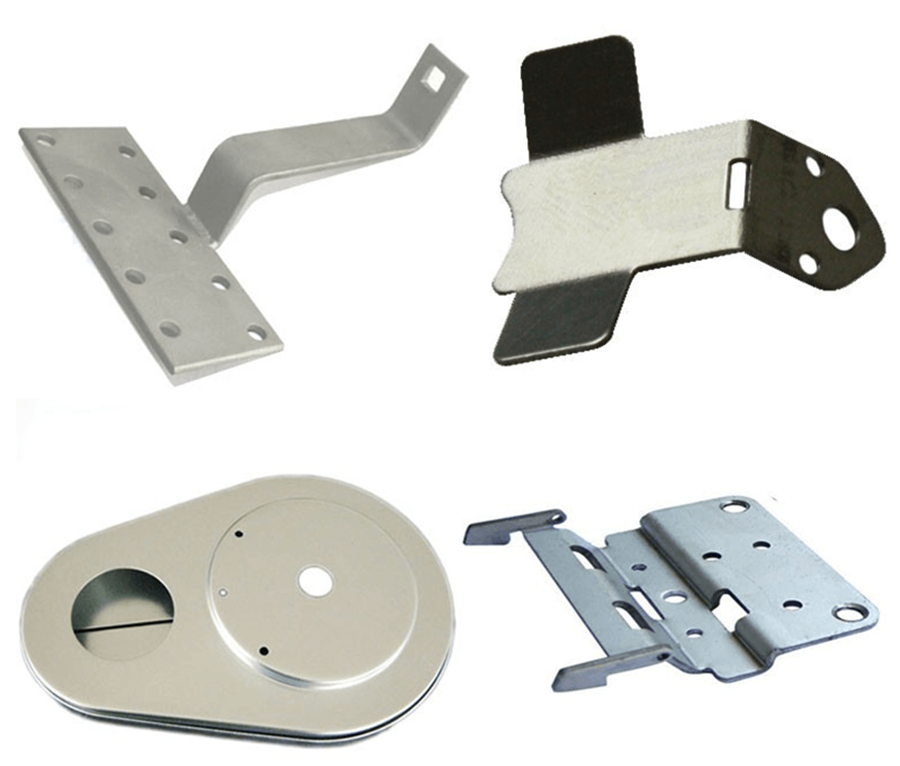

Products description

Material: Stainless steel, carbon steel, aluminum and brass

Precision: ± 0.1-0.2mm

Surface Treatment: Polishing, powder coating, brush, anodized, sandblasting, etc.

Quality control: ISO 9001:2008

OEM Service: Available

Application: Metal Bracket Fabrication

Products show

Product detail pictures:

Related Product Guide:

Our goal is to provide high quality products at competitive prices, and top-notch service to customers around the world. We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for 2019 Good Quality Sheet Metal Stamping Parts - OEM Custom Precision Steel Stamping Part – Mingda , The product will supply to all over the world, such as: Croatia, Johannesburg, South Africa, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!