100% Original Vacuum Sand Moulding - OEM Custom Grey Iron Casting – Mingda

100% Original Vacuum Sand Moulding - OEM Custom Grey Iron Casting – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Soluble Die Casting

Application: Machinery Parts

Machining: CNC Machining

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Grey iron, or grey cast iron, is a material type of cast iron with graphitic microstructure. We call this kind of material grey iron because of the gray color of the fracture. For the graphite lubricating the cut and breaking up the chips, grey iron is a common cast alloy due to its relatively low cost and good machinability. Besides, because the graphite flakes self lubricate, it also has good galling and wear resistance.

Grey iron also has less solidification shrinkage than other cast irons because of the graphite microstructure. Whe casting, the silicon element can promote good corrosion resistance and increase fluidity when casting. Gray iron is generally considered easy to weld. Compared to other iron castings, gray iron has a low tensile strength and ductility; that is why the impact and shock resistance of this kind of material is almost non-existent.

Frequently Used Grey Iron Grades

| Gray Iron | Wall thickness/mm | C | Si | Mn | P≤ | S≤ |

| HT150 | <30 | 3.3-3.5 | 2.0-2.4 | 0.5-0.8 | 0.2 | 0.12 |

| 30-50 | 3.2-3.5 | 1.9-2.3 | 0.5-0.8 | 0.2 | 0.12 | |

| >50 | 3.2-3.5 | 1.8-2.2 | 0.6-0.9 | 0.2 | 0.12 | |

| HT200 | <30 | 3.2-3.5 | 1.6-2.0 | 0.7-0.9 | 0.15 | 0.12 |

| 30-50 | 3.1-3.4 | 1.5-1.8 | 0.8-1.0 | 0.15 | 0.12 | |

| >50 | 3.0-3.3 | 1.4-1.6 | 0.8-1.0 | 0.15 | 0.12 | |

| HT250 | <30 | 3.0-3.3 | 1.4-1.7 | 0.8-1.0 | 0.15 | 0.12 |

| 30-50 | 2.9-3.2 | 1.3-1.6 | 0.9-1.1 | 0.15 | 0.12 | |

| >50 | 2.8-3.1 | 1.2-1.5 | 1.0-1.2 | 0.15 | 0.12 |

In our foundry, we can make grey iron castings in below two types:

Lost Foam Casting: The only investment casting process for cast iron components, which has lots of advantages to produce small gray iron invesmtent castings, such as saved mould cost, shorten production cycle and improve production efficiency. With lost foam casting process, we can help our customers to obtain high accuracy products with excellent surface finish, and less machining operations will be done.

Resin Sand Casting: Main sand casting process for small and medium castings. Compare with other sand casting processes, resin sand casting is relatively precise casting method close to investment casting. As good rigidity of resin sand and high strength of sand mould when early casting,then we could effectively eliminate the shrinkage cavity, shrinkage defects of gray iron castings.

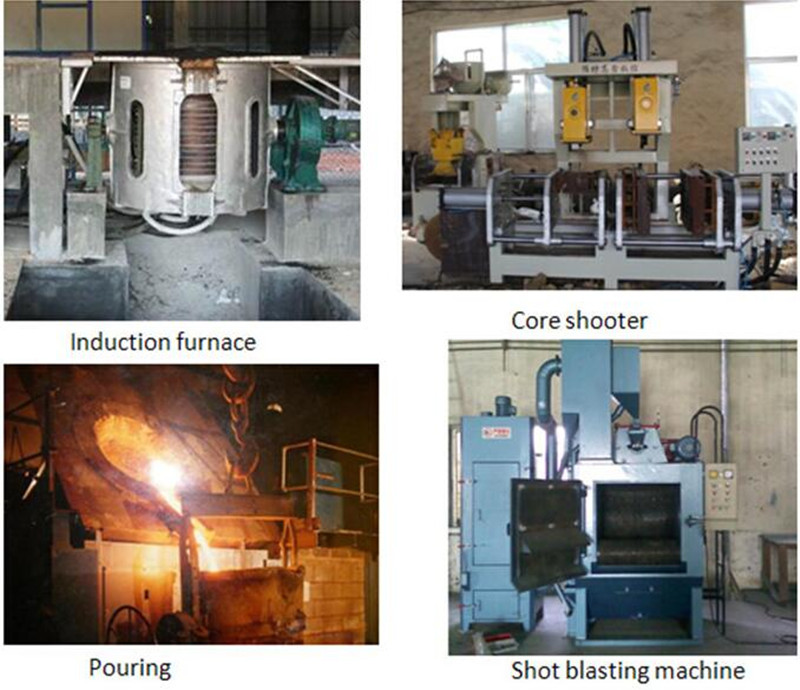

Casting equipment

Product detail pictures:

Related Product Guide:

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for 100% Original Vacuum Sand Moulding - OEM Custom Grey Iron Casting – Mingda , The product will supply to all over the world, such as: Karachi, French, Poland, What is good price? We provide customers with factory price. In the premise of good quality, efficiency must be paid attention to and maintain appropriate low and healthy profits. What is a fast delivery? We make the delivery according to customers' requirements. Although delivery time depends on the order quantity and the complexity of it, we still try to supply products in time. Sincerely hope we could have long term business relationship.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.