100% Original Vacuum Sand Moulding - High Pressure Aluminum Gravity Casting – Mingda

100% Original Vacuum Sand Moulding - High Pressure Aluminum Gravity Casting – Mingda Detail:

Basic Info

Die Casting Machine Type: Cold Chamber Die Casting Machine

Die Casting Method: Precision Die Casting

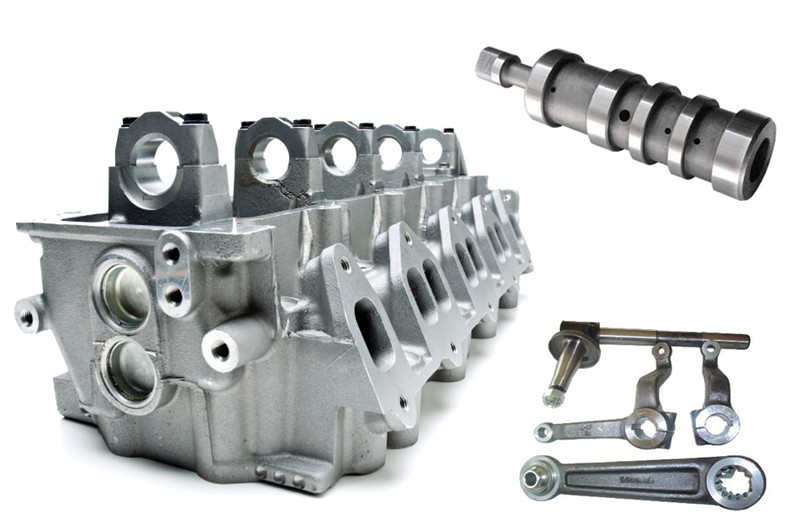

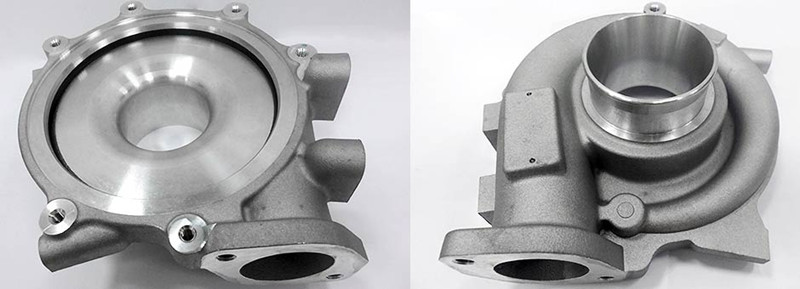

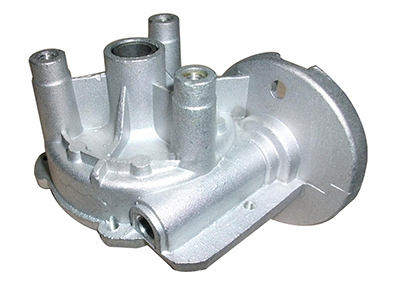

Application: Machinery Parts

Machining: CNC Machining

Material: Aluminum

Surface Preparation: Polishing

Pressure Chamber Structure: Vertical

Tolerance Grade: 8

Casting Surface Quality Level: 3

Certification: SGS, ISO 9001:2008

Size: As Per Drawing

Additional Info

Packaging: standard export package

Productivity: 100 Ton/Month

Brand: Mingda

Transportation: Ocean,Land,Air

Place of Origin: China

Certificate: ISO9001

Port: Tianjin

Product Description

Aluminum Gravity Casting

Unlike aluminum die casting, gravity casting is the casting technique that utilizing gravity to fill the mould with liquid aluminum alloy. Such gravity casting can also be called as aluminum gravity die casting or aluminum permanent mold casting.

Aluminum Gravity Casting Process

Like other casting processes, aluminum gravity casting process starts from the developping of mold by CNC machines. Then, melt aluminum ingots into liquid status, and pour the aluminum liquid water into the permanent molds to fill the cavity by handwork or by gravity casting machines. Next, cool the poured aluminum alloy for a while for solidification.Finally, take the aluminum gravity casting blanks from the mould, and remove the flash and carry out necessary post operations like shot blasting, machining and others. Below is a video showing the aluminum gravity casting process in our foundry.

Benefits of Aluminum Gravity Casting

- The tolerances and surface finish are good.

- Gravity die casting method is competitive casting method when production quantity is relatively small or when heat treatment is needed to improve the mechanical properties.

- This casting method gives better tolerances and surface finish than sand casting. But the tooling costs are a bit higher than by sand casting.

- Using sand cores in gravity die casting makes it possible to manufacture items with complicated inner shapes in a cost effective way in small and medium quantities.

Products show

Product detail pictures:

Related Product Guide:

We usually keep on with the principle Quality To start with, Prestige Supreme. We've been fully committed to offering our purchasers with competitively priced excellent solutions, prompt delivery and skilled support for 100% Original Vacuum Sand Moulding - High Pressure Aluminum Gravity Casting – Mingda , The product will supply to all over the world, such as: Botswana, Estonia, Singapore, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.